This guest post was submitted by Alex Dragas.

It is always fascinating to consider how mankind has evolved over the years in the arena of printing technology. A technology without which communication channels would have had never developed themselves into what they are today. Most of us got acquainted with the dot-matrix, laser and 3D printing technology at later stages because it took them a lot of time to become cheap enough to be commercialized. The same stands true for 4D printing except that it is on its way to revolutionizing the printing technology industry. Before we delve into how 4D printing is changing the world, let us first understand the basics of 3D and 4D printing technologies.

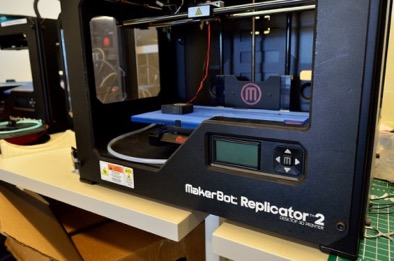

The Basic Mechanics of 3D Printing

The printing of 3D images begins with a 3D designing process in a Computer Aided Design (CAD) software which is used to produce a 3D image in a CAD file format. The object to be printed is digitally processed under certain specifications in a CAD software. Another available option for input is a file obtained by 3D scanning. This scanned file can then be remodeled for a desired output in a 3D modeling software.

When a proper digital input of a 3D image has been recorded and finalized, the software then slices the object into about hundreds of horizontal layers. After the slicing has been done, the printer takes the appropriate command from the software and prints out the 3D image by printing the object layer by layer whilst seamlessly infusing plastic filaments along. The entire process can take—depending upon the quality and size of the image—anywhere from 10 minutes to about 48 hours. [Source: Ink Station]

The 4D Printing Technology

The 4D printing technology has added another valuable dimension to 3D printing—Time! It is this one exclusive and vital feature in 4D printing that has set it apart from all the other evolutionary printing technologies developed since the woodblock printing circa 200 AD.

In the aforementioned technology, the process is much the same as that of a 3D printing technology with one exception. With the addition of the time factor in 3D images, the images begin to change and transform with time under certain defined stimuli.

In 4D printing, a multitude of materials are used based on their water absorption coefficients. Put simply: the different materials when exposed to a variegated range of heat, light, pressure or humidity, will absorb water at different rates resulting in the fluctuation of expansion and rarefaction of the different materials which ultimately outputs a bending and folding image that alters its shape depending upon the environment it is exposed to.

4D Printing | Inspirational Designs on Auto-Pilot

With the auto bending and folding features, one cannot imagine all the possible multitude of designs that can be seen in just one object. Please remember that the auto bending and auto folding features in the images are dependent on light, pressure, heat and humidity. As these natural elements’ proportions keep changing constantly in nature with time, the designs on a 4D print will also change accordingly. A design seen in summer will be different than the one seen in monsoons and accordingly the ones in winter will be absolutely different. The possibilities of a 4D print automatically producing its own designs—with adaptability—are endless. Industries that are dependent on designs, are exploiting this feature of the 4D printing technology to generate hundreds of ideas for inspiration on the fly.

4D Printing | A Healthy Blessing

Medical industry has taken advantage of the 4D printing to save human lives. In the not too distant future we shall witness 4D printing technology being employed for various implants and reconstructive surgery. As of today, 4D printing is helping doctors successfully in dealing with respiratory issues in babies and discoveries are expected for 4D printing’s assistance in facial reconstruction and rebuilding ears with biomedical scaffolds in adults. [Source: Computer World]

4D Printing | Buildings That Will Build Themselves

Skylar Tibbits from the renowned Massachusetts Institute of Technology has predicted that 4D printing technology can make materials build themselves. In traditional architecture, static materials are assembled to give the building a desired shape. With 4D technology, 3D materials can be automatically changed with its adaptability to our use and the environment. Tibbits (as cited in: BBC) is of the view that architecture can have lighter and resilient structures with the aid of 4D technology.

Conclusion

As noted above, 4D printing technology has truly revolutionized our planet during recent times. 4D printing technology is actually a history that’s in the making. From a multitude of ideas generated automatically, to medical aid, to construction of lighter and resilient structures, 4D printing technology is different from the ubiquitous 3D and predated printing technologies. 4D is definitely a ’game changer’ as it has influenced a lot of industries right now and will soon persuade other industries to exploit its unique features for technological advancement.